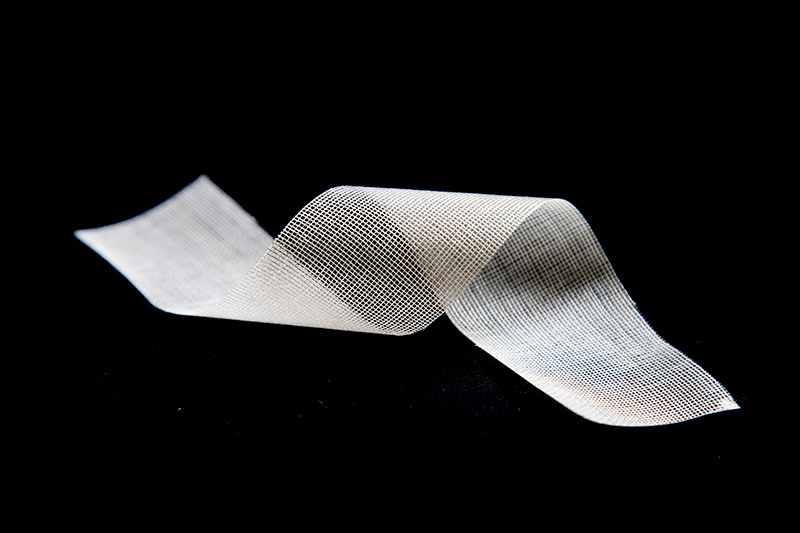

Product Introduction:

The ProtoneX reinforced proton exchange membrane utilizes a high-strength PTFE mesh as its supporting layer, combined with perfluorosulfonic acid resin of optimal molecular weight and ion exchange capacity. This design gives it exceptional chemical resistance and durability, making it widely applicable in high-salt wastewater treatment, electrodialysis, and other water treatment fields.

Product advantages:

1. The Proton exchange membrane for water treatment we produce has high mechanical strength, can work stably under high pressure conditions, and has strong durability.

2. The surface of the Proton Exchange Membranes for Industrial Use we produce is smooth, not easy to be attached by pollutants, and reduces the frequency of cleaning and maintenance.

3. The Composite Ion Exchange Membrane for Water Treatment we produce can work stably in a wide pH range and is suitable for various water treatment environments.

Thickness and Basis Weight Properties:

| Membrane Type | Thickness(microns)(um) | Weight(g/m²) |

| PXWT-220-T01 | 220 | 290 |

Physical and Other Properties:

| Physical and Other Properties | Typical Value | Test Method |

| Tensile Test (23°C, 50% RH) | ||

| Tensile Strength(MPa) | >40 | ASTM D882 |

| Elongation at Break(%) | >100 | ASTM D882 |

| Specific Gravity | 1.32 | — |

| Conductivity(S/cm) | >0.100 | GB/T 20042.3-2022 |

| Acid Capacity(meq/g) | 1.00±0.05 | GB/T 20042.3-2022 |

Hydrolytic Properties:

| Hydrolytic Properties | Typical Value | Test Method |

| Water Content(%) | 5.0±3.0 | ASTM D570 |

| Water Uptake(%) | 50.0 ±5.0 | ASTM D570 |

| Thickness Swelling Rate, % increase,(23°C, 50% RH) | ||

| 23°C soaked(% )from 50% RH | ≤5 | ASTM D756 |

| 100°C soaked(% )from 50% RH | ≤10 | ASTM D756 |

| Linear Expansion, % increase(23°C, 50% RH) | ||

| 23°C soaked(% )from 50% RH | ≤2 | ASTM D756 |

| 100°C soaked(% )from 50% RH | ≤5 | ASTM D756 |

Product Applications of Proton Exchange Membrane For Water Treatment:

Proton Exchange Membranes for Industrial Use is an indispensable material in a large number of technologies from water treatment to energy storage, all of which use electromembrane processes. Composite Ion Exchange Membrane for Water Treatment is regarded as one of the key materials in energy storage devices, such as reverse electrodialyzers for fuel cells, especially redox flow batteries (RFBs). In addition to energy storage, Composite Ion Exchange Membrane for Water Treatment can also be used in separation processes such as desalination, metal recovery or dialysis desalination and electrodialysis.

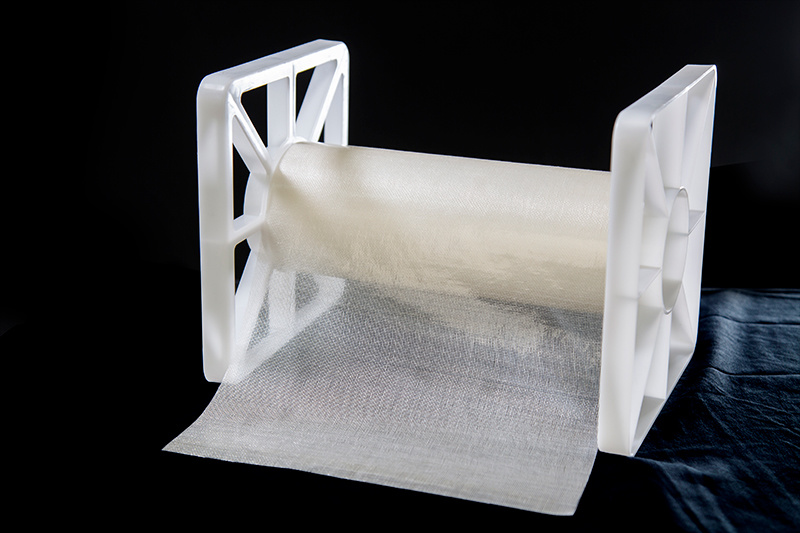

Packaging:

Protective film wrapping: Use protective film to wrap each piece of Proton exchange membrane for water treatment to prevent scratches or contamination on the surface of the film.

Individual packaging: Each piece of Proton Exchange Membranes for Industrial Use is individually packaged in an antistatic bag or vacuum bag to prevent friction between the films and static damage.

Desiccant placement: Place desiccant in the packaging bag to prevent moisture from entering the package and affecting the performance of Proton Exchange Membranes for Industrial Use.

Notes:

Storage conditions: The membrane should be stored in a cool, dry, well-ventilated place, away from direct sunlight and high temperature environment to prevent aging of the membrane material.

Avoid contact with pollutants: During operation, avoid contact with grease, solvents, dust and other pollutants to avoid affecting its performance.

Operating environment: The environment for operating and installing the membrane should be kept clean to prevent dust and other impurities from entering the membrane system.