Enhance Ion Exchange and Increase Chemical Production:

The key performance indicators for a chemical production facility are chemical purity, high yield, and process efficiency. To achieve superior production quality, chemical manufacturers require durable resins, efficient membranes, and high-performance catalysts.

These resins, membranes, and catalysts must consistently perform in extremely harsh conditions to produce high-purity materials and optimize production processes.

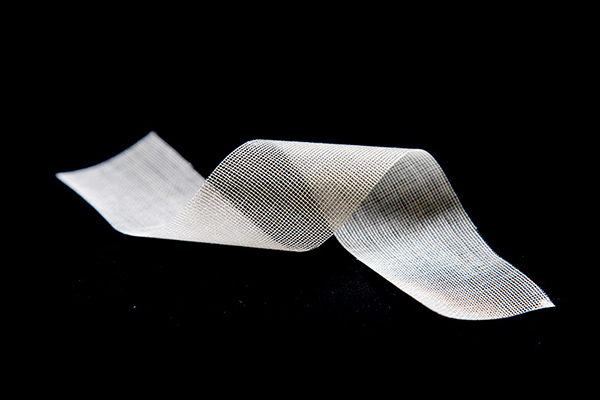

ProtoneX™ ion-exchange materials are essential in various chemical processing applications. These membranes, dispersions, and resins assist producers of ultra-high purity chemicals in enhancing both yield and quality, offering exceptional performance and durability across a wide range of chemical industry uses. These applications include:

Ion Exchange: ProtoneX™ resins function as durable, perfluorinated cation exchange resins, capable of withstanding extreme temperatures and harsh chemical conditions where non-fluorinated resins would fail.

Electrolysis: The selective properties of ProtoneX™ membranes in electrochemical processes enable the production of ultra-high purity compounds, essential for industries like semiconductor manufacturing.

Catalysts: ProtoneX™ polymers serve as super-acid catalysts, and when used in solid pellet form, they can be reused multiple times, helping to reduce overall ownership costs.