1. Role of Membranes

Membranes in electrolytic hydrogen production devices serve three functions: they transmit ions (such as hydroxide or hydrogen ions) in the electrolyte, prevent the crossover or penetration of hydrogen and oxygen between the electrodes, and provide insulation to prevent electron transfer between electrodes (thus preventing conductivity).

Currently, there is significant focus on ion transmission and gas barrier properties, but insulation is often overlooked. Conductivity in membranes leads to high current density and low resistance, resulting in explosions; thus, conductive membranes pose a greater danger than gas crossover.

2. Development of Membranes

The historical choices in membrane materials include asbestos membranes and polyphenylene sulfide membranes.

3. Relationship Between Electrolytic Cell Accidents and Membranes

Conductivity of Membranes as a Major Cause of Accidents

The quality of membranes in the domestic market varies widely. In terms of conductivity, membranes exhibit different resistances, with insulating membranes being the standard for qualification. Some manufacturers lower membrane resistance to enhance conductivity, which directly causes electrolytic cell explosions. Electron transfer in membranes can manifest in several ways:

Low membrane resistance results in attractive operational parameters and minimal energy consumption (below 4.0, even around 3.7).

Despite appealing data, hydrogen production is significantly below theoretical values, as most energy converts to heat, making the membrane a heat-generating component. The heat generation from membranes arises from two points:

During the preparation of polyphenylene sulfide membranes, other types of fibers are introduced that have low dielectric constants and certain electron transfer capabilities.

Modification of membranes may introduce substances that facilitate electron transfer, such as sulfur atoms in polyphenylene sulfide, or impurities like metal ions or surfactants.

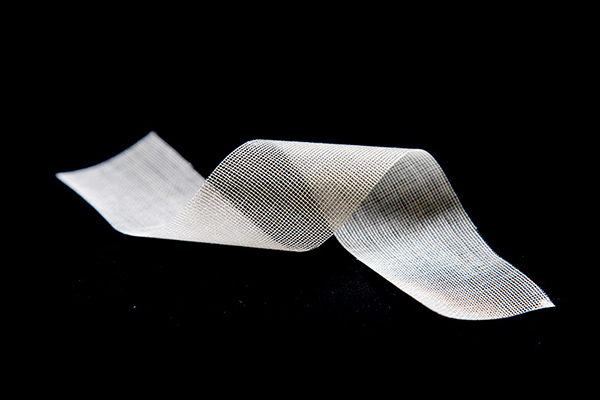

Thin Membranes with Large Pores

Thin membranes with large pores are susceptible to deposition and penetration from detached electrode materials, leading to conductivity. Some manufacturers produce membranes with excessively large gaps in fibers or yarns, resulting in wider pore distribution (5-20 microns) and insufficient thickness. Metal particles (like nickel) in the electrolyte accumulate on and penetrate the membrane, ultimately causing it to become conductive. To prevent conductivity from detached electrodes, membranes must have:

Adequate thickness to prevent metal particle infiltration.

Small pore sizes, ideally below 8-10 microns, preferably with a multilayer structure.

Poor Resistance to Temperature, Corrosion, and Mechanical Damage

The market offers a variety of membranes, but to enhance manufacturing performance, polyphenylene sulfide fibers are often mixed with other structural fibers (resulting in excessive alkali loss and low temperature resistance). Lowering membrane resistance and fiber twist can also compromise mechanical durability. Improper methods to enhance hydrophilicity can lead to issues. Observable membrane characteristics include:

High shrinkage rates.

Elevated alkali loss.

Decreased gas-tightness after external forces.

The operating environment within electrolytic cells can be more destructive than external conditions, necessitating membranes that are resistant to tension, bending, and compression, while still maintaining performance under certain stress levels.