In the process of water electrolysis for hydrogen production, Proton Exchange Membrane (PEM) electrolyzers and Anion Exchange Membrane (AEM) electrolyzers offer distinct features and application benefits. Here’s an overview of their main differences:

Membrane Material

PEM Electrolyzers use proton exchange membranes, typically made from perfluorosulfonic polymers like ProtoneX or Nafion, which conduct protons (H+).

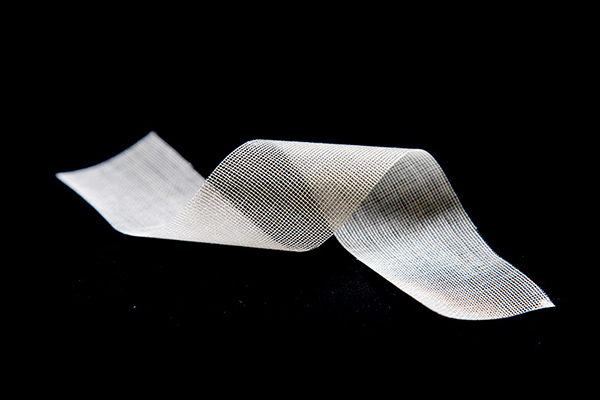

AEM Electrolyzers use anion exchange membranes, often made from polymers with positively charged functional groups, such as polystyrene sulfonate (PSSA), polysulfone sulfonate (PSA), polyether sulfone sulfonate (PES-SA), and others, conducting hydroxide ions (OH-).

Electrolyte

PEM Electrolyzers typically operate with pure water or dilute acidic solutions.

AEM Electrolyzers can use dilute alkaline solutions or pure water, offering more flexibility in material selection.

Catalysts

PEM Electrolyzers require catalysts that can withstand acidic environments. Platinum (Pt) is commonly used for hydrogen evolution at the cathode, while iridium oxide (IrO2) is used for oxygen evolution at the anode.

AEM Electrolyzers can use non-precious metal catalysts in alkaline environments, which helps reduce costs.

Operating Environment

PEM Electrolyzers operate in acidic conditions, necessitating materials with high acid resistance and chemical stability.

AEM Electrolyzers function in alkaline environments, enabling the use of a wider range of materials, including lower-cost, non-corrosive, non-precious metals.

Efficiency and Cost

PEM Electrolyzers are considered highly efficient due to their high current density and ability to produce high-purity hydrogen, though they tend to be more expensive.

AEM Electrolyzers combine the cost benefits of alkaline electrolysis with the simple efficiency of PEM systems, offering advantages like rapid start-up and low energy consumption.

Technology Maturity

PEM Electrolyzers are relatively mature and have already been commercialized for hydrogen production and fuel cell applications.

AEM Electrolyzers are still in the development phase. While they offer low cost and ease of operation, further research is needed to improve product lifespan and scalability for hydrogen production.

System Design

PEM Electrolyzers require careful consideration of the chemical stability and mechanical strength of the proton exchange membrane, as well as the durability of precious metal catalysts.

AEM Electrolyzers require attention to membrane conductivity, alkaline stability, and the choice of catalysts and materials that are compatible with alkaline environments.

Application Potential

PEM Electrolyzers are ideal for applications requiring high-purity hydrogen, such as hydrogen sources for fuel cells.

AEM Electrolyzers show great potential in large-scale renewable hydrogen production due to their low cost and ease of operation when integrated with renewable energy sources.

In summary, both PEM and AEM electrolyzers have their unique strengths. The choice between the two technologies depends on specific application needs, cost-efficiency analysis, and operational conditions. As research progresses, innovations in AEM materials and system designs may open up new market opportunities for large-scale hydrogen production.