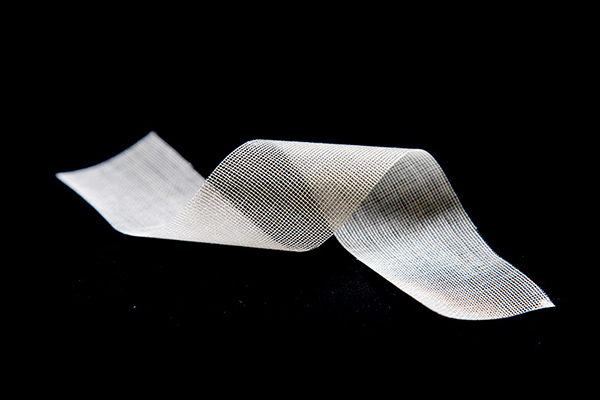

PEM electrolyzers utilize thin proton exchange membranes (0.2 mm) and advanced structured electrodes, which allow for lower resistance and higher efficiency. The perfluorosulfonic acid proton exchange membrane (PFSA) possesses chemical stability and mechanical robustness, capable of withstanding high pressure differentials of up to 70 Pa. However, the acidic environment, high voltage, and oxygen evolution at the anode create a harsh oxidative environment. Therefore, noble metals like iridium or platinum are required as electrode materials, which not only provide long-term stability for the cell components but also excellent electronic conductivity, thereby enhancing reaction efficiency. The high cost of noble metal catalysts contributes to the higher expense of PEM stacks compared to alkaline electrolyzers.

The design of PEM electrolyzer systems is compact and straightforward, yet they are sensitive to water impurities such as iron, copper, chromium, and sodium, and are prone to fire hazards. Currently, the electrode area of PEM electrolyzers approaches 2000 cm², but there remains a significant gap to achieve MW-level targets with single stacks. Additionally, the reliability and lifespan of large MW-level PEM electrolyzers still require validation.

PEM system components are much simpler than those of alkaline systems, typically requiring only a circulating pump, heat exchanger, pressure control, and monitoring equipment on the anode (oxygen) side. On the cathode side, components such as gas separators, deoxygenation equipment for removing residual oxygen, gas dryers, and compressors are usually needed. PEM systems can operate under atmospheric, differential, and balanced pressure conditions, which helps reduce costs, system complexity, and maintenance expenses.

Balanced Pressure Condition: Both sides of the electrolyzer operate at the same pressure, controlled by valves regulating the oxygen and hydrogen pressures.

Atmospheric Pressure Condition (<1 atm): When water is present on the anode and the cell voltage exceeds the thermal neutral cell voltage at ambient temperature, hydrogen and oxygen are generated at the electrodes.

Differential Pressure Condition: The PEM membrane electrolyte can operate under a pressure differential of 3-7 MPa, but a thicker membrane is required to enhance mechanical robustness and reduce gas permeation to ensure efficiency. Additionally, extra catalysts are typically needed to convert hydrogen that permeates due to high pressure back into water.