Challenges and Innovations in Hydroxide Exchange Membrane Fuel Cells (HEMFC)

Fuel cells, which convert chemical energy directly into electrical energy, are widely used in hybrid or zero-emission vehicles and other transportation tools. Hydroxide exchange membrane fuel cells (HEMFC) are an environmentally friendly alternative to traditional acid-based fuel cells. However, HEMFCs are highly sensitive to carbon dioxide (CO2) in the air. The presence of CO2 drastically reduces fuel cell performance and efficiency, by as much as 20%, making HEMFCs almost as inefficient as gasoline engines in some applications.

Innovative Solution: Electrochemical CO2 Separator (EDCS)

Recently, Yan Yushan and Brian P. Setzler’s research team from the University of Delaware published an article in Nature Energy, titled “A shorted membrane electrochemical cell powered by hydrogen to remove CO2 from the air feed of hydroxide exchange membrane fuel cells.” This study introduces a breakthrough electrochemical CO2 separator (EDCS) that effectively removes CO2 from the incoming air of HEMFCs, greatly enhancing their performance.

The EDCS utilizes a unique short membrane technology, allowing it to be powered by hydrogen, similar to a fuel cell, but without the need for wires, bipolar plates, or current collectors. This novel short membrane approach is modular and can be encapsulated in spiral-wound modules, increasing the surface area and volume ratio for more compact and efficient operation.

Commercialization Potential: A Game-Changer for Fuel Cells

Research shows that a 25cm² short membrane EDCS module can effectively remove more than 99% of CO2 from air at 2000 SCCM over 450 hours. In fact, these modules can handle up to 10,000 SCCM of air, removing over 98% of CO2. For an 80kW net HEMFC stack, the cost of a compact and efficient module capable of removing over 99% CO2 is only $112. This represents a significant step forward in making fuel cell technology more affordable and commercially viable.

The simplicity of the EDCS module, with fewer components, translates to lower costs and greater scalability. This positions the technology as a promising solution for widespread adoption, not only in fuel cells but also in specialized applications like spacecraft and submarines for life support systems.

Relevance to Our Products

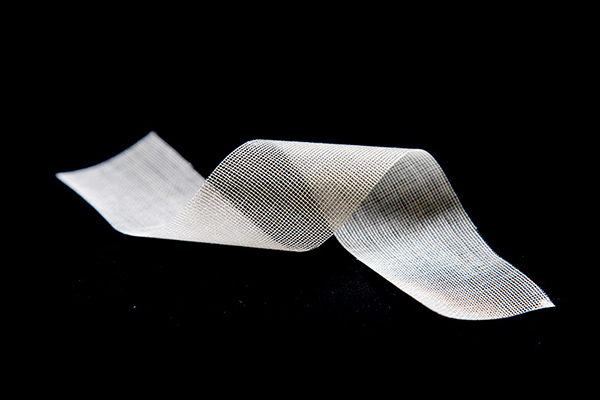

As hydrogen energy technology continues to evolve, particularly in water electrolysis and hydrogen fuel cell applications, our Proton Exchange Membranes (PEM) and Mixed Anion Exchange Membranes play a critical role in ensuring high performance and long-term stability in these systems. Our membrane products align perfectly with the green hydrogen revolution.

Our PEM membranes are designed for high conductivity, low gas permeability, and high pressure resistance, making them ideal for both water electrolysis for hydrogen production and hydrogen fuel cells.

The Mixed Anion Exchange Membranes we manufacture improve upon the performance of traditional membranes, addressing issues like ion contamination and enhancing durability, making them more suitable for long-term applications.

As highlighted by this breakthrough in CO2 separation, the future of the hydrogen energy industry is bright. We believe our high-performance PEM membranes are well-positioned to contribute significantly to the advancement and commercialization of green hydrogen solutions.

Conclusion

With the ongoing development of hydrogen energy technologies, innovations like the electrochemical CO2 separator (EDCS) are key to improving fuel cell efficiency and reducing costs. Our advanced PEM membranes are central to these innovations, helping drive the hydrogen energy industry forward. Whether in hydrogen production, fuel cells, or energy storage systems, our products offer unmatched performance and reliability.

For more information or partnership inquiries, feel free to contact us.