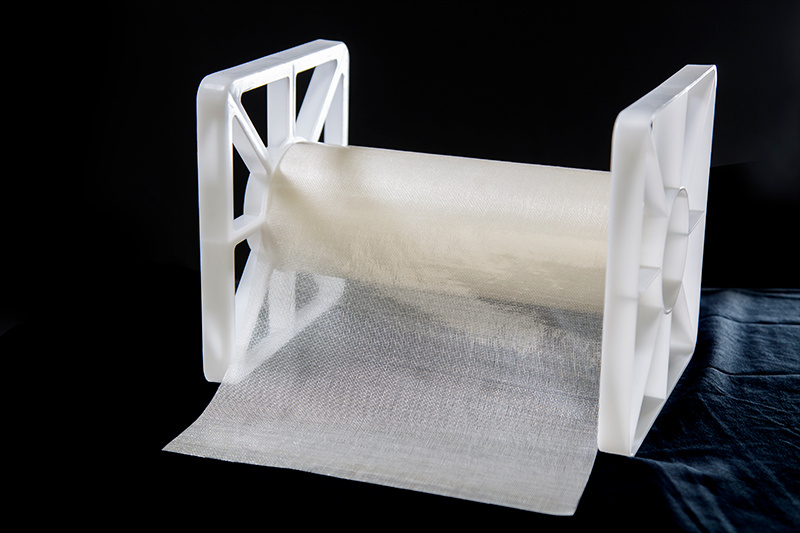

Product Introduction Of Ionic Exchange Membrane:

The Enhanced Ion Exchange Membrane we produce adopts a special casting process and selects perfluorosulfonic acid resin with optimal molecular weight and ion exchange capacity. The Enhanced Ion Exchange Membrane we produce has the characteristics of uniform thickness. The Enhanced Ion Exchange Membrane we produce is widely used in various electrolytic application fields such as chlorine dioxide generators, copper recovery in etching solutions, gold salt production, amino acid refining, caustic soda production, electrodialysis, and related electrolytic industries.

Product Advantages Of Ion Exchange Membrane:

The ion exchange membranes we produce are suitable for the refining, recovery and chemical preparation of various metals such as gold, silver and copper, providing a variety of application possibilities. The ion exchange membranes we produce are made of sustainable materials and are easy to recycle, supporting environmental protection and sustainable development goals.

Thickness And Basis Weight Properties:

| Membrane Type | Thickness(microns)(um) | Weight(g/m²) |

| PXEL-260-T01 | 260 | 340 |

Physical And Other Properties:

| Physical and Other Properties | Typical Value | Test Method |

| Tensile Test (23°C, 50% RH) | ||

| Tensile Strength(MPa) | ≥40 | ASTM D882 |

| Elongation at break(%) | ≥100 | ASTM D882 |

| Specific Gravity | 1.35 | — |

| Other Properties | Typical Value | Test Method |

| Conductivity(S/cm) | >0.100 | GB/T 20042.3-2022 |

| Acid Capacity(meq/g) | 1.00±0.05 | GB/T 20042.3-2022 |

Hydrolytic Properties:

| Hydrolytic Properties | Typical Value | Test Method |

| Water Content(%) | 5.0±3.0 | ASTM D570 |

| Water Uptake(%) | 50.0±5.0 | ASTM D570 |

| Thickness Swelling Rate, % increase (23°C, 50% RH) | ||

| 23°C soaked (%)from 50% RH | ≤5 | ASTM D756 |

| 100°C soaked (%)from 50% RH | ≤10 | ASTM D756 |

| Linear Expansion, % increase(23°C, 50% RH) | ||

| 23°C soaked from 50% RH | ≤2 | ASTM D756 |

| 100°C soaked from 50% RH | ≤5 | ASTM D756 |

Storage Environment Of Ion Exchange Membrane:

Before use, please store Enhanced Ion Exchange Membrane in a clean, dry and temperature-controlled environment. Avoid prolonged exposure to extremely high or low temperatures to prevent material performance degradation.

The storage area is well ventilated and the membrane material is not exposed to direct sunlight or ultraviolet light for a long time to prevent aging.

Avoid direct contact with harmful chemicals such as organic solvents, strong acids and alkalis, and oxidants during storage to prevent chemical corrosion.

Notes Of Ion Exchange Membrane:

Measurements taken with membrane conditioned to 23℃, 50% RH for 24h.

Conductivity measurement taken at 23℃, 100% RH.

A base titration procedure by using the caustic soda measures the equivalents of sulfonic acid in the membrane, thus calculating the acid capacity or equivalent weight of the membrane.

Water content of membrane conditioned to 23℃ and 50% RH (dry weight basis).

Water uptake of dry membrane conditioned in water at 100℃ for 1 hour (dry weight basis).