Trends in Hydrogen Energy Development

Hydrogen energy is a secondary energy source that is abundant, green, low-carbon, and widely applicable. It is gradually becoming one of the important carriers in the global energy transition. China is the largest hydrogen producer in the world, having initially mastered key technologies and processes related to hydrogen production, storage, transportation, and refueling, thus forming a relatively complete hydrogen energy industrial chain. In recent years, China's hydrogen energy industry has developed rapidly, attracting numerous participants and producing a number of well-known companies with strong competitive power. Currently, leading companies in the industry have established competitive advantages through enhancing technological research and development, streamlining industrial chain links, building sales networks, and cultivating professional talent.

In the future, as the hydrogen energy industry continues to evolve, customer demands for hydrogen production will increasingly rise, leading to stronger industry consolidation. The market share of leading companies will gradually increase, and barriers to entry in the hydrogen energy sector will become more pronounced. To achieve carbon peak and carbon neutrality goals, China has positioned hydrogen energy as an important part of its future national energy system, a key vehicle for achieving green and low-carbon transformation at energy end-use terminals, and a focal point for strategic emerging industries and future industrial development.

In response to national policies, companies are actively practicing the dual-carbon strategy, employing mature technologies to ensure long-cycle, stable, and reliable operation. Alkaline water electrolysis for hydrogen production primarily relies on technology to capture the market, quality to consolidate it, and service to expand it. Driven by market demand, led by technology, and focused on quality for reputation, with innovation as the path for development, the industry aims to truly achieve zero emissions and pollution, long service life, digital monitoring and operation, safety, and unmanned operation modes, with excellent quality, timely supply, reasonable pricing, and top-notch service.

Hydrogen energy boasts advantages such as zero pollution, high calorific value, and versatility in storage and application. Electrolysis of water can utilize renewable energy and surplus fluctuating electricity to produce hydrogen, making it one of the most ideal and environmentally friendly methods for hydrogen production. Therefore, the development of renewable energy electrolysis for hydrogen production is significant for energy security and CO2 reduction. However, currently only 4% of hydrogen globally is produced through water electrolysis, primarily due to high costs associated with this method, where electricity consumption and electrolyzer costs are key constraints to large-scale application.

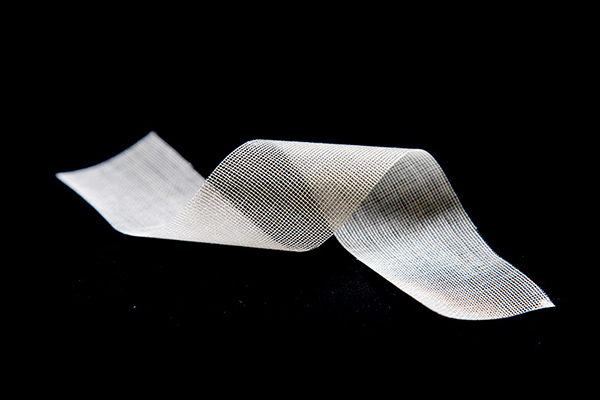

Under the impetus of the dual-carbon goals, advancements in renewable energy generation technologies are expected to drive down electricity prices, serving as a powerful catalyst for the development of the water electrolysis hydrogen production industry. Alkaline electrolysis technology is gaining attention for its low cost, long lifespan, and abundant material sources, making it suitable for large-scale hydrogen production. However, in large-scale hydrogen production applications, it is still necessary to further enhance the current density and energy efficiency of alkaline electrolysis technology to improve its equipment and electricity cost. The membrane and electrode materials play a crucial and irreplaceable role in this process.

Future Outlook for Water Electrolysis Hydrogen Production Technology

The cost of hydrogen production through water electrolysis mainly depends on electricity costs, electrolyzer investment costs, and operating loads, with electricity costs influencing hydrogen production sensitivity by up to 60-70%. As electricity costs decline, the proportion of equipment investment costs will gradually increase. Future cost-reduction drivers will mainly stem from lower electricity prices, increased equipment utilization rates, and technological advancements to reduce electrolyzer costs. However, as alkaline electrolyzer technology is already very mature, the extent to which costs can be reduced through technological innovation is limited. With further industrial development, future application scenarios will continue to broaden, and large-scale, low-cost, and low-energy consumption are recognized as consensus for industrial development.

Classification of Technological Routes for Water Electrolysis Hydrogen Production

There are four main technological routes for hydrogen production through water electrolysis: alkaline water electrolysis (ALK), proton exchange membrane water electrolysis (PEM), solid oxide electrolysis (SOEC), and anion exchange membrane water electrolysis (AEM).

Alkaline Electrolysis (ALK): This process is carried out in an alkaline electrolyte solution (typically KOH), where OH- ions pass through the membrane to the anode, losing electrons to produce O2, while water at the cathode gains electrons to produce H2 and OH-.

Proton Exchange Membrane Electrolysis (PEM): This method electrolyzes pure water, where H2O molecules are oxidized at the anode to generate oxygen and H+ ions. The H+ (protons) migrate through the proton exchange membrane to the cathode under the influence of the electric field and undergo a reduction reaction to generate hydrogen gas.

Solid Oxide Electrolysis (SOEC): This process involves ionizing water vapor to generate hydrogen and oxygen ions at high temperatures, typically above 600°C, making it suitable for producing high-temperature, high-pressure steam in solar thermal power systems.

Anion Exchange Membrane Electrolysis (AEM): This process usually uses pure water or low-concentration alkaline solution as the electrolyte, where OH- ions pass through the exchange membrane to reach the anode to generate water and oxygen, while water molecules at the cathode produce OH- and hydrogen gas.

Comparison of Hydrogen Production Process Routes

Each method has its own strengths and limitations:

Alkaline Electrolysis (ALK)

Advantages: Currently the most mature technology with low equipment costs.

Limitations: Corrosive liquid; high operation and maintenance costs; theoretical efficiency is lower than that of PEM and SOEC; challenging to apply in intermittent power sources.

Proton Exchange Membrane Electrolysis (PEM)

Advantages: High adaptability to intermittent power sources, easy to integrate with renewable energy like wind and solar; low operation and maintenance costs.

Limitations: High equipment costs; requires precious metal catalysts.

Solid Oxide Electrolysis (SOEC)

Advantages: High theoretical efficiency; can use non-precious metal catalysts.

Limitations: High-temperature reaction environment, limited application scenarios; still in the laboratory R&D stage and not yet commercialized.

Anion Exchange Membrane Electrolysis (AEM)

Advantages: Combines the advantages of alkaline and PEM: low material costs; low corrosiveness of electrolyte (dilute alkaline solution or water); does not require precious metal catalysts.

Limitations: Difficulties in mass production of anion exchange membranes, still in the R&D phase.

The alkaline electrolysis route is mature, PEM shows strong growth potential, while SOEC and AEM have promising future potential.