A complete flow battery energy storage system typically includes the power unit (electrolyte stack), energy unit (electrolyte and electrolyte storage tank), electrolyte delivery unit (piping, pumps, valves, sensors, etc.), and battery management system. Among these, the power unit is the core element that determines the system’s power scale, while the energy unit plays a decisive role in the system’s energy storage capacity. The two units operate independently but in coordination to support the overall function of the flow battery energy storage system.

Flow Battery Production Process: A Complete Breakdown

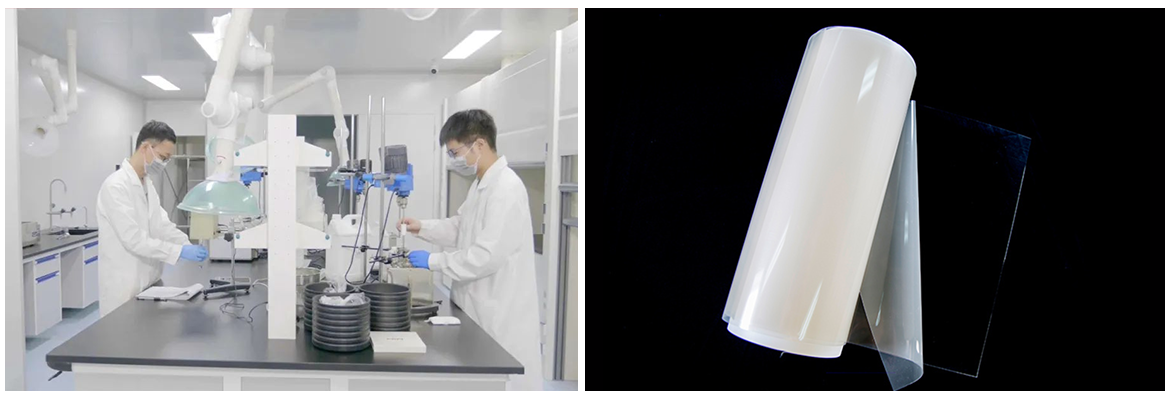

Electrolyte Stack AssemblyThe production process begins with the assembly of the electrolyte stack after the preparation of key materials. The first step is to use laser welding technology to fuse the bipolar plates and membranes into a unified seal to prevent leakage. This laser welding process has unique advantages, such as achieving instant heating, melting, and solidifying, which ensures no deformation of the overall stack. Compared to traditional methods like heat plates, hot melt glue, or sealing rings, laser welding improves welding efficiency by over five times. Additionally, the heat-affected zone during laser welding is usually controlled within ±1mm, effectively reducing the negative effects of high temperatures on electrolyte performance. This application not only enhances the stack’s reliability but also improves assembly automation and reduces the use of sealing materials, thus lowering the stack’s cost.

After laser welding, the next steps are stacking and tightening. The sealed bipolar plates, membrane seals, and other components are stacked according to the required sequence and number. After compressing and sealing, the components are secured with bolts, completing the stack assembly.

Leakage and Charge/Discharge Performance TestingOnce the stack assembly is complete, it is moved to the testing equipment for leak testing. Non-compliant products are sent back for resealing through the laser welding process. Compliant products then move to the next step—charge/discharge performance testing. The key focus in this stage is to ensure the stability of the testing environment, consistency in charge/discharge cut-off, and the uniformity of the electrolyte state, all of which are critical for accurate and reliable test results.

Electrolyte FillingThis step uses an automatic liquid injection system. First, the battery stack undergoes a vacuum treatment to create a negative pressure environment, followed by the automatic injection of electrolyte through a filling port. The entire process occurs under normal temperature and fully sealed conditions to prevent external factors from interfering with the electrolyte and stack performance.

Energy Storage System Integration and AssemblyThe final step is the integration and assembly of the energy storage system. Multiple finished stacks, metal frames, piping, accessories, electrolyte tanks, magnetic pumps, and electrical control systems are assembled into a standardized energy storage system.

In addition to the specialized equipment used in these core production steps, other general auxiliary equipment is necessary, such as cooling towers, exhaust purification systems, air compressors, and pure water systems. While these auxiliary devices do not directly participate in the core production steps, they play an indispensable role in ensuring the smooth production process, maintaining environmental stability, and guaranteeing product quality.

Key Materials in Flow Battery Production

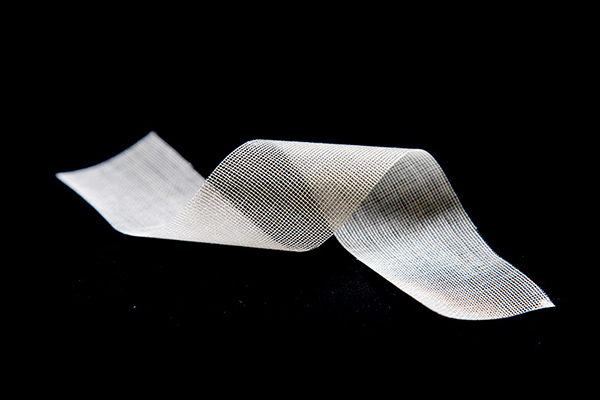

MembraneThe membrane, also known as the ion exchange membrane, is extremely crucial in vanadium flow batteries. It isolates the positive and negative electrodes from the electrolyte, preventing short circuits and cross-contamination, while maintaining ion balance in the system. The permeability, stability, and cost of the membrane are critical factors for the commercialization of flow batteries.

Based on the fluorine content, there are various types of membranes, including perfluorosulfonic acid membranes, partially fluorinated membranes, non-fluorinated membranes, and composite ion exchange membranes. Perfluorosulfonic acid membranes, due to their high conductivity, low proton resistance, and mechanical strength, are the only ones that have been commercialized, while others are still in the experimental phase.

Bipolar PlatesBipolar plates are a key component in flow batteries, responsible for connecting the cells in series, conducting current, and supporting the electrodes. The ideal material for bipolar plates should have good conductivity, electrochemical stability, corrosion resistance, and mechanical strength.

Materials used for bipolar plates include metals, graphite, composite materials, and integrated electrode-bipolar plates. Graphite plates are favored for their good conductivity and chemical stability, but they have low mechanical strength, are brittle, difficult to process, expensive, and hard to mass-produce. Composite bipolar plates combine the advantages of both metal and graphite, making them the emerging mainstream choice. Integrated electrode-bipolar plates combine the electrode and bipolar plate into a single unit, improving battery performance and ease of assembly, but the process is more complex and expensive.

ElectrolyteThe electrolyte is a core material in flow batteries, directly influencing the performance and cost of the energy unit. The volume and concentration of the electrolyte determine the maximum energy storage capacity of the system, while the purity, stability, and temperature range of the electrolyte affect the battery’s efficiency and lifespan.

For example, in vanadium flow batteries, electrolyte and power unit costs each account for approximately 50% of the initial investment. As the charge/discharge time increases, the cost of electrolyte becomes a larger proportion. The main methods for preparing vanadium electrolytes include physical dissolution, chemical reduction, and electrolysis, with electrolysis being the most common method for large-scale production.

Industry Challenges and Opportunities

Cost Pressures and Technological Breakthroughs: Vanadium flow batteries still face relatively high production costs. Reducing these costs and improving efficiency will be key to the industry’s future development. Technological breakthroughs, such as the development of new electrolytes, may help lower costs and enhance performance.

Policy Support and Market Opportunities: Global policy changes in the energy storage industry will create new investment opportunities for flow batteries. Vanadium flow batteries, with their high energy density and long lifespan, have unique advantages in the market. As the demand for renewable energy increases, flow batteries are expected to play a growing role in the energy storage sector.

Competition and Future Directions: Flow batteries face competition from new energy storage technologies such as lithium-ion and sodium-ion batteries. To capture a larger market share, the flow battery industry will need to focus on technological innovation and industry cooperation.

Supply Chain Cooperation and Capital Market Opportunities: Companies along the flow battery supply chain can achieve mutually beneficial development through deeper collaboration. Additionally, the growth of the flow battery industry presents new investment opportunities for the capital markets.