As the world moves toward clean and sustainable energy, hydrogen production has become a key focus in the quest for decarbonization. Electrolysis is one of the most promising methods for producing green hydrogen, and various electrolyzer technologies are used to convert water into hydrogen. Below is a quick overview of the main electrolyzer technologies, highlighting the differences and advantages, with a special focus on PEM and AEM electrolyzers.

1. Alkaline Electrolyzer (AEC)

The most mature and widely used electrolyzer technology, AEC has been in operation for decades. It uses a liquid alkaline solution, typically potassium hydroxide (KOH), as the electrolyte. While reliable and cost-effective, AEC has lower efficiency compared to other modern technologies and typically operates at a lower current density.

2. Proton Exchange Membrane Electrolyzer (PEM)

PEM electrolyzers represent a more advanced and efficient technology for hydrogen production. These use a solid polymer membrane as the electrolyte and are capable of operating at higher current densities and pressures than AEC systems. PEM electrolyzers are especially suited for renewable energy integration, as they can respond quickly to fluctuating power inputs from sources like solar and wind. They also have a higher efficiency in terms of energy conversion, making them a key technology for future hydrogen production.

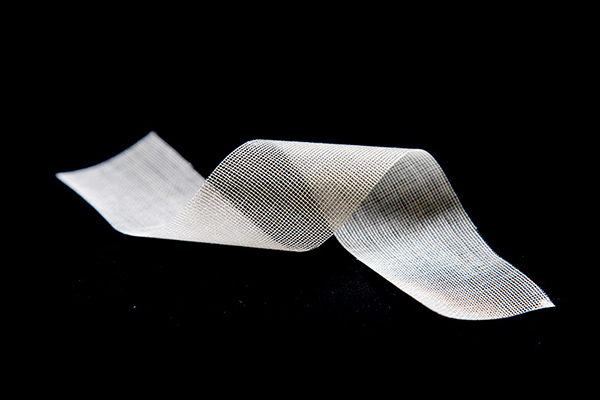

3. Anion Exchange Membrane Electrolyzer (AEM)

AEM electrolyzers are an emerging technology that uses an anion exchange membrane to facilitate the electrolysis process. This membrane allows for the transport of hydroxide ions (OH-) instead of protons (H+), making them a promising alternative to PEM electrolyzers. AEM electrolyzers share many advantages with PEM technology, including high efficiency, compact size, and the ability to operate with renewable power sources. The key benefit of AEM is its potential for cost reduction, as it can use less expensive materials, such as non-precious metals, for the electrodes.

4. Solid Oxide Electrolyzer (SOEC)

SOEC is a high-temperature electrolysis technology that operates at temperatures of 700–1000°C. This high temperature allows for higher efficiency by using both electricity and heat for the electrolysis process. While SOEC has great potential in terms of efficiency, its high operating temperature requires advanced materials and makes it less suited for intermittent renewable energy sources.

Conclusion: PEM vs. AEM - The Future of Electrolysis

While all of the above electrolyzer technologies have their advantages, the future of green hydrogen production is likely to be shaped by PEM and AEM electrolyzers.

PEM Electrolyzers are already widely adopted in the industry due to their efficiency, flexibility, and ability to work with renewable energy. They provide excellent performance even under variable operating conditions and offer high purity hydrogen.

AEM Electrolyzers are gaining traction because they offer the same advantages as PEM, but at a lower cost due to the potential for using cheaper materials. AEM electrolyzers are still in development, but their progress is promising, and they may become a competitive alternative to PEM in the near future.

In conclusion, both PEM and AEM electrolyzers are poised to play a critical role in the future of sustainable hydrogen production. The key to choosing the right technology will depend on specific use cases, cost considerations, and the integration with renewable energy systems.