As green hydrogen technology continues to advance globally, selecting the optimal hydrogen production membrane thickness for electrolyzers has become crucial in maximizing efficiency. Whether in alkaline electrolyzers or PEM electrolysis systems, the membrane thickness directly impacts three key performance metrics:

Ionic Conductivity (Resistance)

Gas Purity (Crossover)

Mechanical Longevity

Understanding the relationship between membrane thickness and electrolyzer performance is not only vital for optimizing hydrogen production, but it is also a key component in improving the overall efficiency of green hydrogen technology systems.

The Trade-offs of Thin vs. Thick Membranes in Electrolyzers

Thin Membranes (<0.5mm): Fast Ion Transfer with Trade-offs

Thin membranes are ideal for PEM electrolysis, as they allow for fast ion transfer, which is crucial for achieving high-efficiency hydrogen production. However, these membranes come with trade-offs:

Gas Purity: Thin ion exchange membranes generally have higher membrane gas permeability, which reduces gas purity to below 99.5%.

Pinhole Risk: After about 2,000 hours of operation, thin hydrogen production membranes may develop pinholes, compromising both efficiency and lifespan.

Through our extensive tests, we’ve found that alkaline electrolyzers benefit from slightly thicker membranes (around 0.8mm) for maintaining gas purity without significant efficiency loss.

Thick Membranes (>1.2mm): Superior Gas Blocking but Higher Overpotential

Thick membranes are widely used in industrial electrolyzer applications due to their superior ability to block gas crossover, ensuring gas purity above 99.99%. However, they present challenges:

Overpotential: Membranes thicker than 1.2mm tend to exhibit overpotentials greater than 200mV, which can reduce overall system efficiency.

Delamination Risk: The increased pressure inside electrolyzers can cause delamination, leading to premature failure in thick membranes.

A study by the International Energy Agency (IEA) highlights that while thick hydrogen production membranes provide better gas purity, they require more energy due to the higher overpotential.

Science-Backed Thickness Optimization

IEA White Paper Findings: Membrane Thickness Optimization in Alkaline Electrolyzers

Sweet Spot: Membrane thicknesses between 0.8-1.0mm provide the best balance between efficiency and membrane lifespan in alkaline electrolyzers.

Key Insight: For every 0.1mm reduction in membrane thickness, ion exchange membrane resistance decreases by 8%, but gas crossover increases by 15%. This trade-off must be carefully balanced to ensure optimal performance for green hydrogen technology systems.

In line with these findings, Protonex’s PXEL-260-T01 membrane, with a thickness of 0.26mm, offers a significant improvement in both efficiency and lifespan compared to traditional membranes.

U.S. DOE Technical Report: Commercial PEM Electrolyzer Membranes

Commercial Thickness Range: Commercial PEM electrolysis membranes typically range from 120-200μm in thickness, offering the optimal balance between ion transfer and gas purity.

Proven Performance: DuPont’s 25μm reinforced hydrogen production membrane has been shown to achieve >40,000 hours of operation at 2A/cm², making it one of the most reliable membranes in the industry.

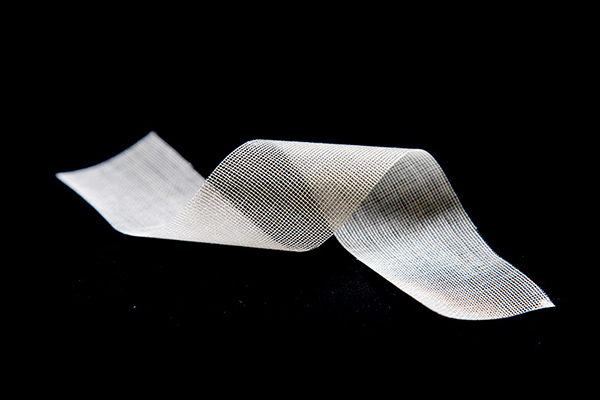

Protonex Solution: PXEL-260-T01 Composite Membrane

Performance Benchmark Comparison

| Parameter | PXEL-260-T01 | Traditional Asbestos |

|---|---|---|

| Thickness | 260μm (0.26mm) | 500-800μm |

| Area Resistance | 0.12Ω·cm² | 0.35Ω·cm² |

| H₂ Crossover | 0.6mL/min·cm² | 1.2mL/min·cm² |

| Lifespan (@1A/cm²) | >25,000h | <8,000h |

Breakthrough Technology:

Graded Density Design: The 50μm dense surface acts as a gas barrier, while the 210μm porous base optimizes ion flow, making it suitable for industrial electrolyzers.

Self-Healing Coating: The CeO₂ nanoparticles within the membrane autonomously repair microcracks, extending the membrane’s service life and improving mechanical longevity.

In a 2023 test with a leading international energy provider, the PXEL-260-T01 membrane showed a 25% reduction in energy consumption compared to traditional PEM electrolysis systems.

Industry Validation

Offshore Wind-to-Hydrogen Project

A recent offshore wind-to-hydrogen project demonstrated an 18% lower energy consumption using Protonex’s advanced hydrogen production membranes, compared to conventional PEM electrolysis systems, contributing both to cost savings and a reduced carbon footprint.

The electrolyzer stack, equipped with PXEL-260-T01 hydrogen production membranes, showed zero degradation in performance after 8,000 operational hours, proving its long-term reliability in real-world applications.

Industrial Testing

PPS hydrogen production membrane for electrolysis showed <2% swelling in 30% KOH, demonstrating its superior chemical stability and resistance to degradation.

About Protonex

Protonex pioneers advanced hydrogen production membrane technologies for the hydrogen economy. Our PXEL series hydrogen production membranes are deployed in over 30 countries, driving the revolution in green hydrogen technology.

For more information, contact us:

📧 heidi.z@protonexm.com

FAQ: Membrane Thickness and Electrolyzer Efficiency

1. What is the optimal hydrogen production membrane thickness for PEM electrolysis?

The optimal thickness typically ranges from 120μm to 200μm for PEM electrolyzers. Thinner hydrogen production membranes allow faster ion transfer but may compromise gas purity, while thicker membranes provide better purity but result in higher overpotentials, decreasing efficiency.

2. How does hydrogen production membrane thickness affect gas purity and efficiency in electrolysis?

Thinner hydrogen production membranes tend to have higher gas permeability, which reduces gas purity. Thicker membranes ensure better gas purity but lead to higher overpotentials, which decreases overall electrolyzer efficiency.

3. What are the benefits of the PXEL-260-T01 hydrogen production membrane?

The PXEL-260-T01 composite hydrogen production membrane provides a perfect balance between ion transfer efficiency and gas purity. With a lifespan of over 25,000 hours at 1A/cm², it outperforms traditional PEM electrolysis membranes in both efficiency and longevity.