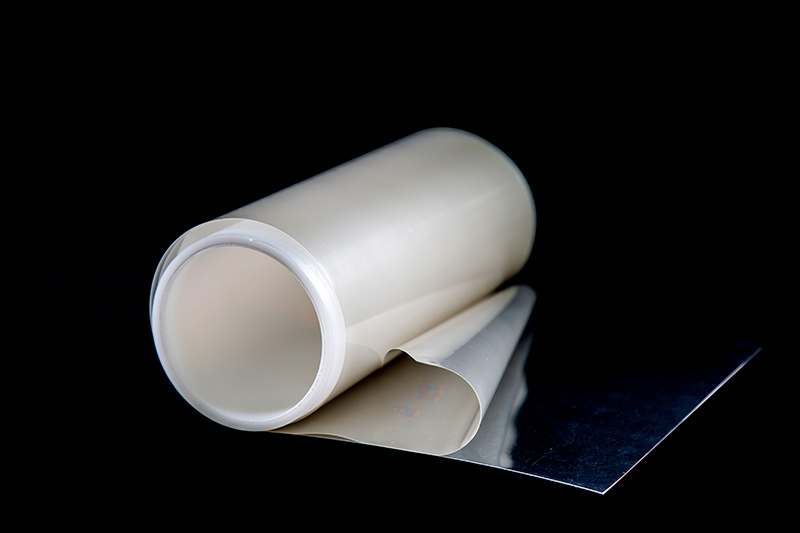

Product Introduction Of Polymer Electrolyte Membrane:

The Polymer electrolyte membrane we produce is an efficient, safe, and environmentally friendly hydrogen production solution with the characteristics of high conductivity, low gas permeability, and high pressure resistance. The Polymer electrolyte membrane we produce uses advanced electrolysis technology, combined with high performance The advanced electrode materials and intelligent electronic control provide users with an economical, reliable and easy-to-operate hydrogen production method. The Polymer electrolyte membrane we produce uses advanced proton exchange membrane technology to achieve efficient electrolysis at high current density, significantly increasing hydrogen production and reducing hydrogen production costs.

Product Advantages Of Polymer Electrolyte Membrane:

The polymer electrolyte membrane we produce is produced using efficient electrolysis devices, providing high hydrogen production with low energy consumption, which is critical to reducing operating costs and improving production efficiency. The polymer electrolyte membrane we produce has excellent chemical and mechanical stability, which can maintain performance under continuous operation and changing operating conditions, extending the service life of the electrolyte membrane. The low resistance design reduces energy consumption during the electrolysis process, making it an energy-saving hydrogen production solution.

Thickness And Basis Weight Properties:

| Membrane Type | Thickness(microns)(um) | Weight(g/m²) |

| PXVA/WE-125-T01 | 125 | 246 |

Physical And Other Properties:

| Physical and Other Properties | Typical Value | Test Method | |

| TensileTest (23℃,50%RH) | |||

| Tensile Strength (MPa) | ≥28 | ≥28 | ASTM D882 |

| Tensile Modulu (MPa) | ≥400 | ≥200 | ASTM D882 |

| Elongation at break(%) | ≥120 | ≥200 | ASTM D882 |

| Specific Gravity | 1.97 | 1.98 | |

| Other Properties | Typical Value | Test Method | |

| Conductivity²(S/cm) | ≥0.100 | ≥0.100 | GB/T20042.3-2022 |

| Acid Capacity³(meq/g) | 1.00±0.05 | 1.00±0.05 | GB/T20042.3-2022 |

| Dissolved Hydrogen Concentration | 1000 | ||

Hydrolytic Properties:

| Hydrolytic Properties | Typical Value | Test Method | |

| Water Content⁵(%) | 5.0±3.0 | 5.0±3.0 | ASTM D570 |

| Water Uptake(%) | 50.0±5.0 | 50.0±5.0 | ASTM D570 |

| Thickness Swelling Rate at 23℃,50%RH(%increase) | |||

| Water soaked at 23℃50%RH | ≤5 | ≤18 | ASTM D756 |

| Water soaked at 100℃50%RH | ≤15 | ≤30 | ASTM D756 |

| Linear Expansion at 23℃,50%RH (% increase) | |||

| Water soaked at 23℃50%RH | ≤5 | ≤16 | ASTM D756 |

| Water soaked at 100℃50%RH | ≤18 | ≤20 | ASTM D756 |

Precautions For Polymer Electrolyte Membrane:

Correct installation: When installing the device, please strictly follow the instructions in the user manual and ensure that all connections are correct and secure. Using non-original or incompatible parts may cause damage to the device or degrade its performance.

Regular inspection: Regularly check the status of the device, especially the electrodes and electrolysis cells, to ensure that they are not corroded or otherwise damaged. If any abnormality is found, stop using it immediately and contact a professional technician for inspection.

Electrical safety: Make sure that the power supply of the device meets the manufacturer's regulations and has good grounding protection. Avoid operating the device in a humid environment to prevent electrical short circuits or other electrical safety issues.

Notes Of Polymer Electrolyte Membrane:

Measurements taken with membrane conditioned to 23℃.50%RH for 24h.

Conductivity measurement at 230.100%RH.

A base titration procedure measures the equivalents of sulfonic acid group in the polymer resin,thuscalculating the acid capacity or equivalent weight of the membrane.

Water content ofmembrane conditioned to 23 ℃ and 50%RH(dry weight basis).

Water uptake fiom dry membrane to conditioned in water at 100'℃ for l hour (dry weight basis).