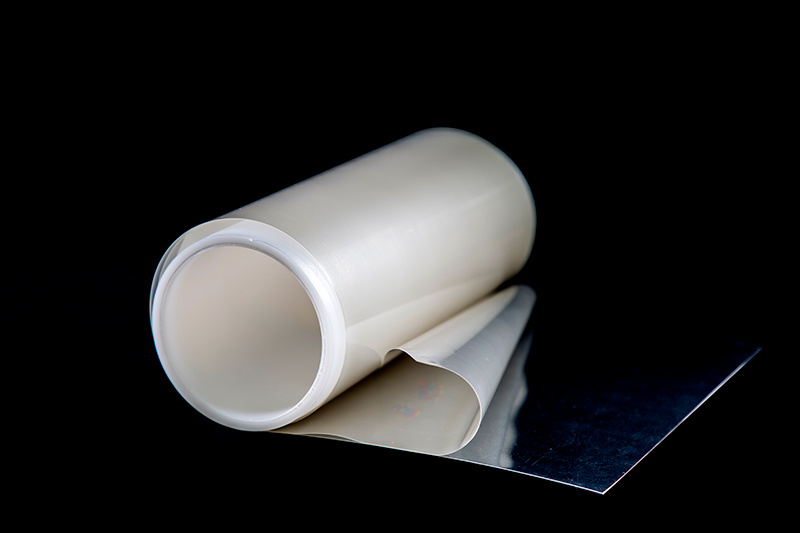

Product Introduction Of Ion Exchange Membrane Electrolysis:

The Polymer exchange membrane we produce is a high-performance proton exchange membrane designed for water electrolysis hydrogen production. It integrates a number of advanced technologies and material optimization to ensure efficient energy conversion and long-term stable operation during water electrolysis hydrogen production. The Polymer exchange membrane we produce can be divided into: PEM for industrial hydrogen production and PEM for civilian hydrogen production according to specific application scenarios. The Polymer exchange membrane we produce has the characteristics of high conductivity, low gas permeability, and high pressure resistance.

Product Advantages Of Ion Exchange Membrane Electrolysis:

The Polymer exchange membrane electrolysis we produce adopts advanced electrolysis technology, combined with high-performance electrode materials and intelligent electronic control. The design of the Polymer exchange membrane electrolysis we produce fully considers the user's operating habits. The simple and intuitive interface makes the operation more convenient and can be operated without in-depth professional training. At the same time, it is easy to maintain, which lowers the user's usage threshold.

Thickness And Basis Weight Properties:

| Membrane Type | Thickness(microns)(um) | Weight(g/m²) |

| PXWE-125W-T01 | 125 | 246 |

Physical And Other Properties:

| Physical and Other Properties | Typical Value | Test Method | |

| TensileTest (23℃,50%RH) | |||

| Tensile Strength (MPa) | ≥28 | ≥28 | ASTM D882 |

| Tensile Modulu (MPa) | ≥400 | ≥200 | ASTM D882 |

| Elongation at break(%) | ≥120 | ≥200 | ASTM D882 |

| Specific Gravity | 1.97 | 1.98 | |

| Other Properties | Typical Value | Test Method | |

| Conductivity²(S/cm) | ≥0.100 | ≥0.100 | GB/T20042.3-2022 |

| Acid Capacity³(meq/g) | 1.00±0.05 | 1.00±0.05 | GB/T20042.3-2022 |

| Dissolved Hydrogen Concentration | 1000 | ||

Hydrolytic Properties:

| Hydrolytic Properties | Typical Value | Test Method | |

| Water Content⁵(%) | 5.0±3.0 | 5.0±3.0 | ASTM D570 |

| Water Uptake(%) | 50.0±5.0 | 50.0±5.0 | ASTM D570 |

| Thickness Swelling Rate at 23℃,50%RH(%increase) | |||

| Water soaked at 23℃50%RH | ≤5 | ≤18 | ASTM D756 |

| Water soaked at 100℃50%RH | ≤15 | ≤30 | ASTM D756 |

| Linear Expansion at 23℃,50%RH (% increase) | |||

| Water soaked at 23℃50%RH | ≤5 | ≤16 | ASTM D756 |

| Water soaked at 100℃50%RH | ≤18 | ≤20 | ASTM D756 |

Precautions When Transporting Ion Exchange Membrane Electrolysis:

Professional packaging: The equipment should be professionally packaged with shockproof materials, such as custom foam plastics or cushioning materials, to protect the equipment from vibration and impact that may occur during transportation.

Suitable transportation environment: Ensure that the transportation environment meets the storage requirements of the equipment, especially temperature and humidity control. If possible, the equipment should be stored in an environment with controlled temperature and humidity for transportation.

Loading and unloading precautions: During loading and unloading, a forklift or other suitable equipment should be used, and the operator should be aware of the weight and size of the equipment to avoid damage during loading and unloading.

Notes Of Polymer Exchange Membrane Electrolysis:

Measurements were made on membranes conditioned at 23°C, 50%RH for 24 hours.

Conductivity was measured at 230.100%RH.

Alkaline titration measures the equivalent weight of sulfonic acid groups in the polymer resin, thereby calculating the acid capacity or equivalent weight of the membrane.

Water content (dry weight basis) of membranes conditioned at 23°C and 50%RH.

Water uptake (dry weight basis) of dry membranes conditioned in water at 100'°C for 1 hour.